APC Installation & Duct Work

Air Pollution Control (APC) Equipment, Ducting & Chimney

APC System mainly consist of following component to operate:

Industrial centrifugal blower as main force to move air. Blower can be made of mild steel, stainless steel, PP housing fan, FRP fan. etc to suit the various conditions of application. Some other specification of blower may require explosion proof fan, marine fan, special make housing,

Filtration unit, to clean the air stream before release to atmosphere, depending on the conditions of treatment required may include cyclone, bags type/cartridge type collector, Electrostatic precipitator (EP), mist collectors, chemical filter house, wet collector etc.

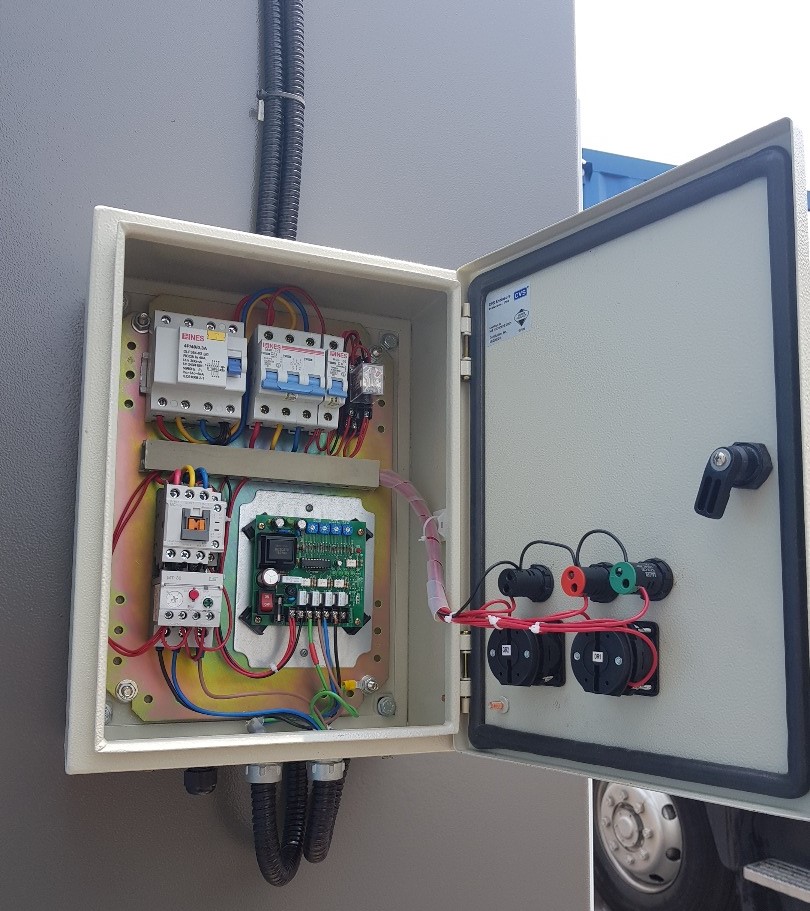

Electrical control panel and wiring for the running of the blower motor and self cleaning filtration unit or other accessories and equipment such as damper, rotary valve, timer controller, purging valve etc.

Ducting with suction accessories for moving dirty air from targeted area to the filtration unit; ducting may make of GI sheet, welding mild steel, stainless steel, PVC or FRP depend on the condition of use.

To design an effective and efficient dust collector system, selection of a correct type of filtration unit, properly calculated fan capacity required, proper designed of duct size and route and a good designed suction hood/method is almost important. either component with improper designed/selection may cause the malfunction of the dust collector system as a whole.

Other Professional work

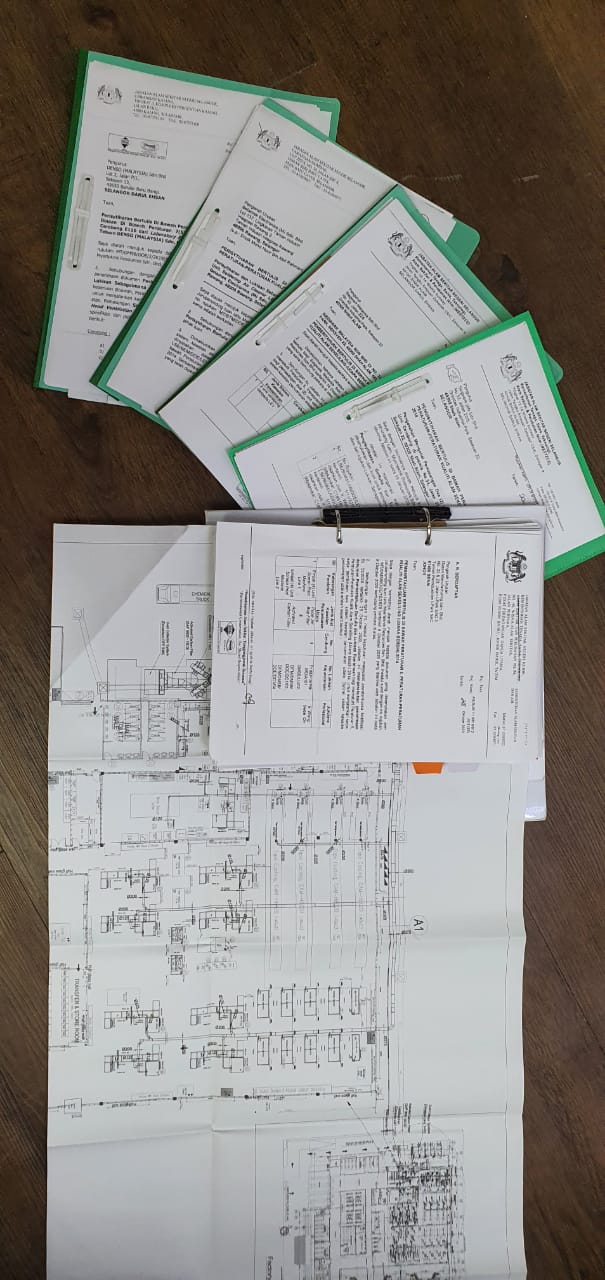

Besides, Design and physical installation work, we do assist customer to prepare report with PE designed & endorsement drawing for the submission to authority for erection and as built notification.

Fan Blower for Dust Collector

Contol Panel

Duct Work

Dust Collector

Chimney Installation

Installation of Cyclone

EP Fume Collector

Wet scrubber

Prepare of submission documents to DOE for APC erection and as built notification